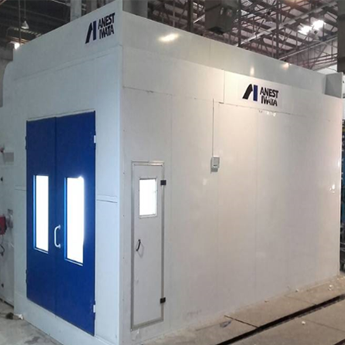

Paint Booths.

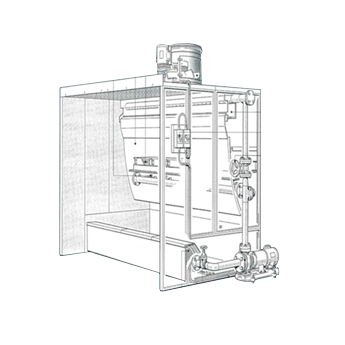

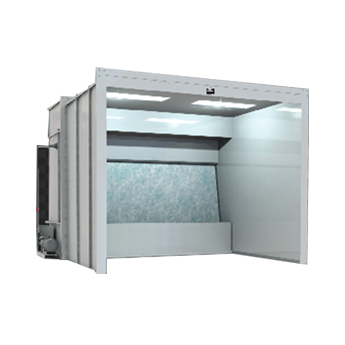

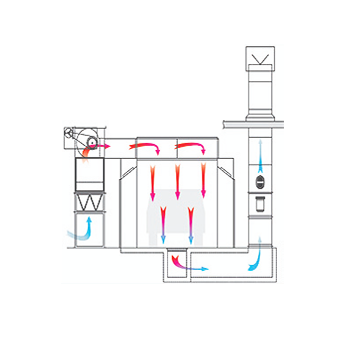

ANEST IWATA offers optimised paint circulation systems right from the selection of best economiANEST IWATA brings its world leading technology and engineering to design customised paint booths, optimised to the maximum (O-MAX) for the specific customer needs after careful study of their process requirements, substrate characteristics and space constraints. These booths are designed to be compliant to environmental regulatory requirements, backed by the globally renowned green technology of ANEST IWATA. binding to each other and prevent paint dust.

A strong team of engineering resources covering electrical, mechanical, project execution and related project areas ensures technical expertise built into the design and provides support right till execution and service stages.

Our objective is to supply high quality and cost effective paint booths with strong after sales support to customers.cal pump, perfect agitation to right sizing of the piping so that traveling velocity of the paint inside the pipe line can hold the paint particles binding to each other and prevent paint dust.