- Home

- Turnkey Solutions

- Flow Coaters

Scroll down

Principle of the Flow Coater

- A stream of paint runs down in the form of a thin curtain (or film) of a fixed width, and the workpiece is painted as a conveyor carries it under the stream.

- We take complete turnkey paint shop projects that cover fully automated installations with painting booths, drying ovens, robots and reciprocators along with paint distribution systems.

Features

- Economical, resource-efficient coating equipment without wasteful use of paint

- Beautiful paint surface with uniformly smooth finish

- High-speed coating at conveyor speeds of 40 to 120 m/min

- Hygienic working environment with no paint mist

- The double-head type flow coater can use two-component paint as well

- Easy to handle; no special coating skill required

Usable Types of Liquid

- Paint

- Adhesive

- Striping Agent

- Photosensitising Agent

- Print Processing Fluid/Dye

- Others

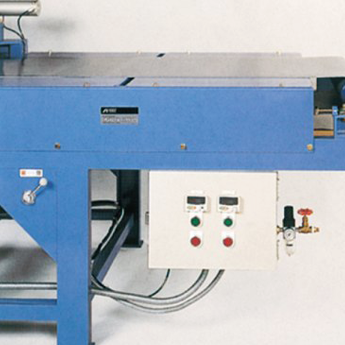

Pump

- Packing-less centrifugal pump with no sliding part

- The pump motor is of the safety-enhanced explosion-proof type

- The pump motor is controlled by an inverter

- The flow rate is displayed in digital form, allowing numerical control and high repeatability

- The paint filter chamber is located outside, making it easy to clean and replace the filter

- The filter bypass makes it easy to inspect, maintain, and replace paint (except FL-3SG/W3G)

- The paint container can be detached and attached easily, and it is also easy to change paint

- The paint container has a structure that allows smooth paint circulation

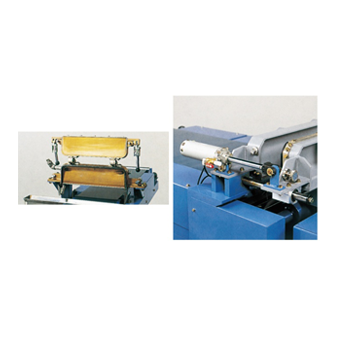

Head

- The head can be opened and closed easily, and it is also easy to clean the inside of the head

- FL-S3G/W3G head is of the hinge type, and FL-S6G/W6G and FL-S12G/W12G are of the horizontal slide type

- FL-S6G/W6G and FL-S12G/W12G use an air cylinder to drive opening and closing motions, which allows the head to be opened and closed with a one-touch operation

- The head space is properly set by a constant-pressure device and a stopper mechanism, which always provides a stable level of repeatability regardless of the operator

- The slit can be fine-tuned anywhere across the entire width of the paint curtain

- The paint capacity of the head is small, ensuring the amount of remaining paint is small

Conveyor

- The conveyor speed is the key point in determining the paint film thickness

- The conveyor speed can be adjusted in a fine-grained manner through inverter control

- Direct speed readings are available

- The conveyor uses an urethane resin belt

- Dirt can be wiped off easily with thinner

- The meandering motion of the belt can be adjusted with the take-up method of the crown mechanism